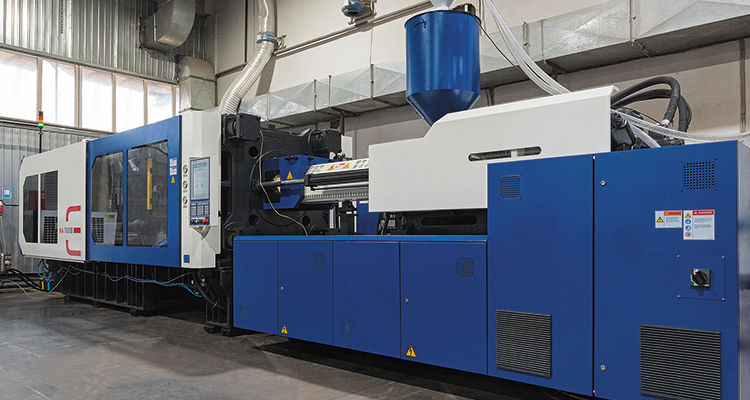

Blauberg Ventilatoren’s production equipment fleet consistently gets upgraded. Recently, the company commissioned nine new injection moulding machines, one of which has unique features. Commissioning new injection moulding machines is associated not only with expanding the production capacities, but also with the need to meet more complex production demands. One new injection moulding machine in particular allows manufacturing more massive and larger products. This machine currently is involved in production of large plastic casings for Blauberg Primo inline mixed flow fans weighing up to 4.5 kg, as well as impellers thereto.

All new injection moulding machines are connected to a unified information network with Wi-Fi access. Such a solution allows centralized real-time managing of all machines in line with production plans and objectives, which results in flexible production process.