Design

- The BSK series dampers are made in the general-purpose industrial version with a minimized variety of hardware components using low-alloy galvanized steel. The flap is made of fire-resistant material (vermiculite) with thermoexpansive fireproof sealing.

- The duct design implies two connection ports for integration into a ventilation duct (duct system).

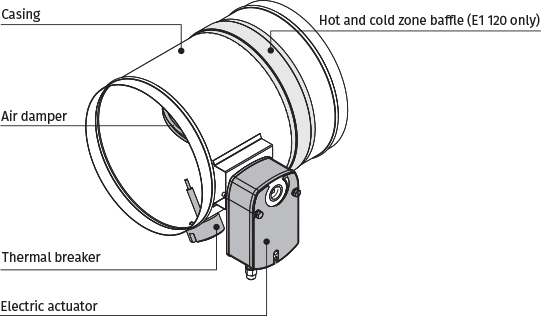

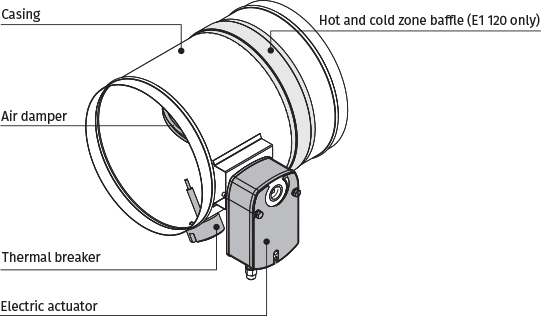

The BSK fire safety damper with an electric actuator and a thermoelectric breaker

Control and modifications

- The BSK series dampers are equipped with an electric actuator with a built-in return spring and a thermally sensitive breaker.

- Setting the damper to operating position (direct fire contact): remotely, via electric actuator. The damper can be set to the operating or protective position either remotely via a control panel or manually using the manual cocking handle which is always included in the standard delivery set of the electric actuator. In case of the remote control panel failure, the back-up thermal breaker interrupts the power supply to the electric actuator and the return spring sets the damper to the operating position. Emergency damper actuation: The damper flap is set to the protective position automatically (damper unaffected by fire). The electric actuator remains energized at all times. In case of an emergency actuation (direct fire contact): The electric actuator equipped with a return spring is de-energized and the damper flap is set to the operating position by means of the spring energy. In case of a power failure not related to fire and its subsequent restoration at the actuator with a return spring, the damper flap returns to a protective position.