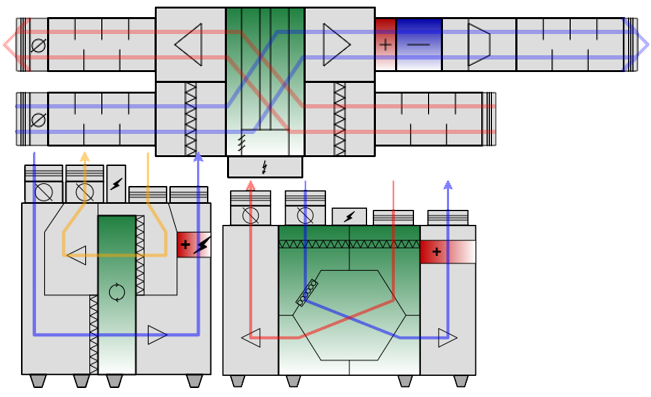

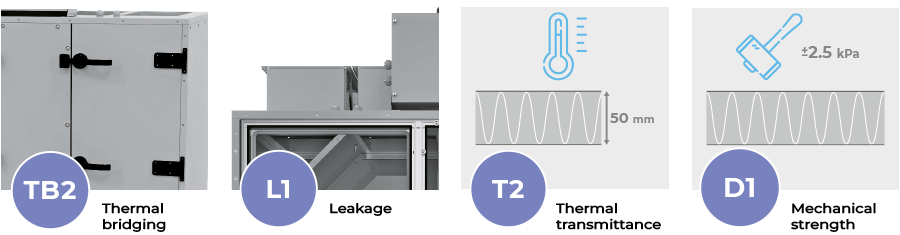

T2 / TB2 / L1 / D1

The construction of the case with a PVC profile ensures the absence of thermal bridges, minimizes heat loss and reduces the noise level.

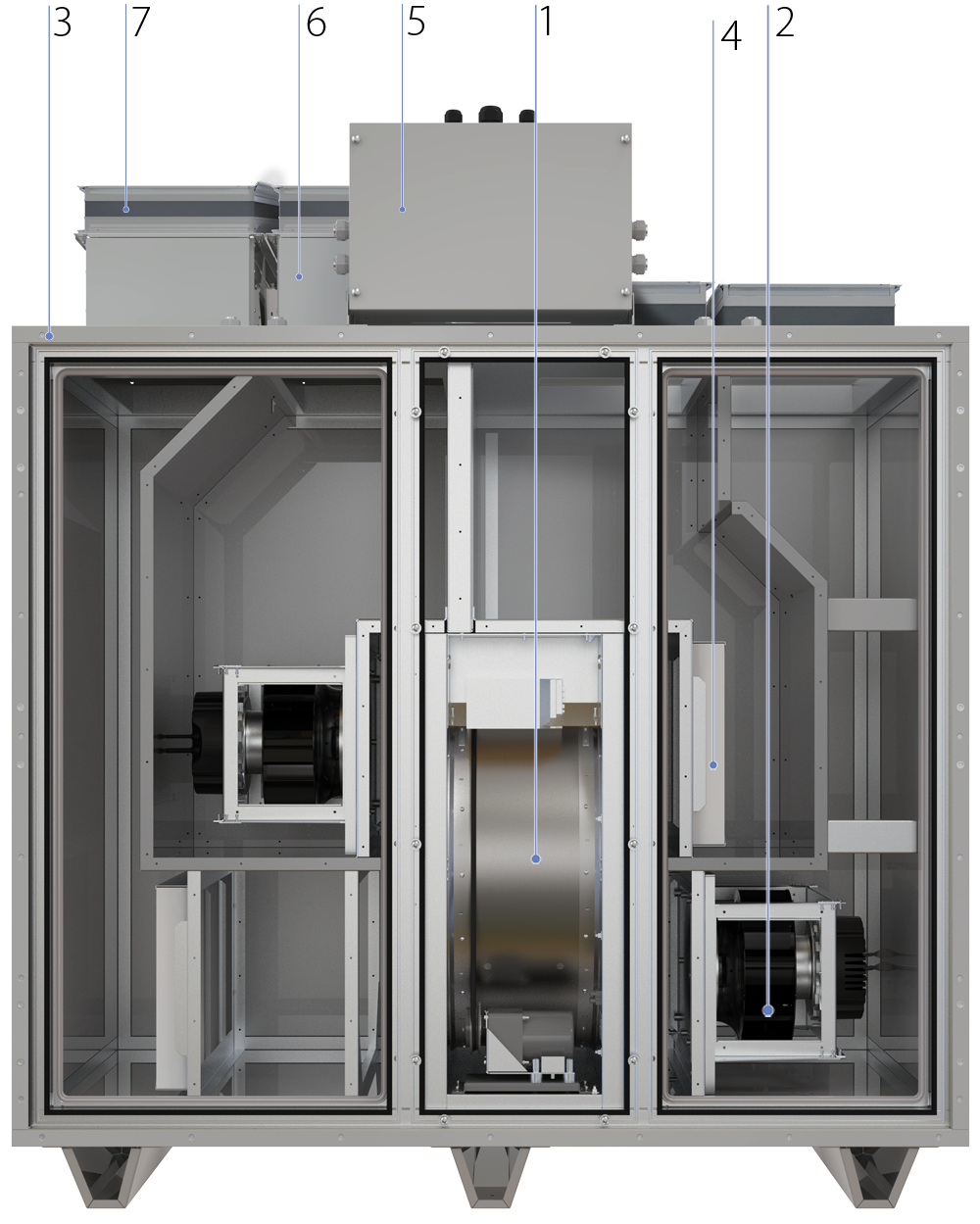

| Size | Nominal air flow, m3/h | Instalation type | Overall hight,

mm | Heat exchanger material | Unit location | Service side | Energy-saving features |

| BLS10 RV1200 | 1200 | floor mounted, vertical | 760 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |

| BLS10 RV1800 | 1800 | floor mounted, vertical | 880 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |

| BLS20 RV2400 | 2400 | floor mounted, vertical | 880 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |

| BLS30 RV3300 | 3300 | floor mounted, vertical | 1200 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |

| BLS40 RV4200 | 4200 | floor mounted, vertical | 1300 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |

| BLS55 RV5400 | 5400 | floor mounted, vertical | 1350 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |

| BLS65 RV6600 | 6600 | floor mounted, vertical | 1350 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |

| BLS95 RV8700 | 8700 | floor mounted, vertical | 1730 | condensation / enthalpy / sorption | indoor | Left/

Right | T2/TB2 |