Ventilation systems produce a heavy load on the electrical systems of a building. Therefore, reducing the power consumption is among the top priorities for construction project designers.

As a rule, smoke extraction systems utilize large high-performance fans. During starting the high inertia of the shaft causes a substantial increase in the start-up time - i.e. the time from the application of power to reaching the rated speed. As a result the motor is subjected to high starting current for a prolonged period of time.

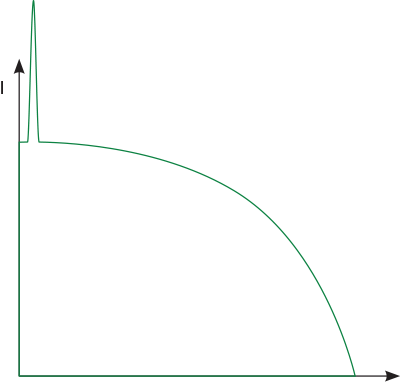

Current diagram with direct on-line starting

Standard switchgear (automatic circuit breakers, contactors and motor starters) is not designed to withstand prolonged overloads causing the fan to shut down automatically during starting. Using switchgear with a higher maximum current rating renders the electric motor protection system less sensitive. As a result the switchgear will not be able to detect motor overload in time due to a higher current sensing threshold. Such challenges can only be addressed by utilizing a soft starter or a frequency converter to start the fan without causing a prolonged overload.

A frequency converter (FC) consists of two main component blocks. One converts alternating current (50 or 60 Hz) into direct current. The other converts direct current into alternating current of variable frequency ranging from 0 to 250 Hz. By controlling the frequency output the FC offers a broad range of motor speed regulation.

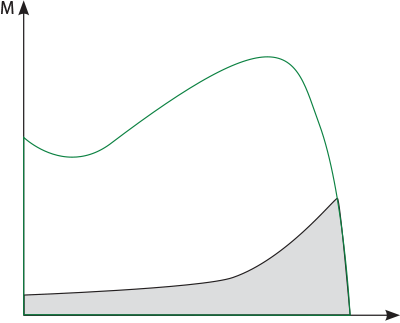

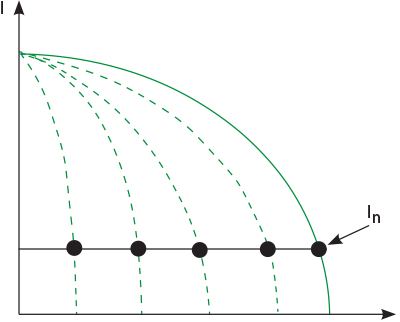

Current diagram with FC starting

During the starting the FC raises the frequency from 0 Hz to the electrical mains frequency (50 or 60 Hz). As the frequency is increased gradually, the motor can be assumed to operate at its nominal speed for a given frequency value. Furthermore, on the assumption that the motor runs at its nominal speed the nominal torque should be immediately available whereas the current will be approximately equal to the nominal value.

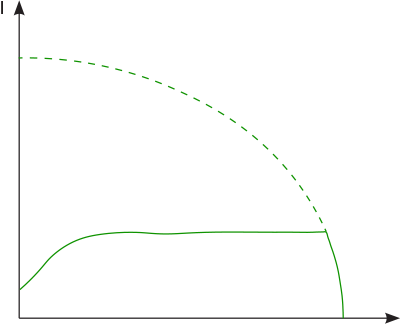

Torque diagram with FC starting

Using an FC or a soft starter allows to reduce the starting current thereby avoiding a loss of voltage in the electrical mains.

In addition to that the starting torque and mechanical strain on equipment are also reduced which translates into extended maintenance and repair intervals.

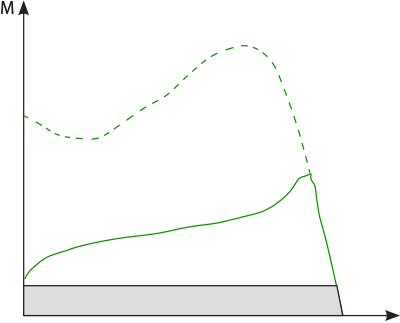

General exhaust ventilation (GV) systems and emergency smoke extraction (SE) systems of car parks, warehouses, utility and industrial spaces can be integrated into a single system at the design level.

As the air flow rate a GV system is considerably lower than that in an SE system a high-capacity fan rated for smoke extraction duty runs in partial load mode.

Frequency converters can be programmed for several fixed-speed settings to enable operation in GV and SE modes.

The fan operating modes can be switched upon receiving an external signal from the control system.

Such integration of ventilation systems allows overall cost savings.

Below you can find two series of frequency converters: FC-51 and FC-101.

The FC-51 series is only suitable for general ventilation systems.

If intended for a smoke extraction system, the fans should be fitted with the FC-101 series units as they feature an integrated fire mode.

When activated the integrated protection equipment of the frequency converter is overridden enabling the unit to continue operation despite the possibility of sustaining irreparable damage due to overheating or overloading.

In case of a fire, the FC-101 series frequency converters are capable of maintaining a higher air pressure level at landings compared to other areas of the building in order to keep the landings smoke-free.